Ultrawear ®

Ultrawear ® is applied to steel components to increase wear resistance. It also increases the material strength properties as well as increasing its resistance to corrosion.

In support of many ‘original equipment manufacturers’ corporate strategies, we have developed a thermal-chemical diffusion process on grey iron rotors, drums and hubs to increase:

- Corrosion resistance

- Wear

- Thermal fatigue

- Serviceability

- Pulsation Reduction

- Increased Pad Life

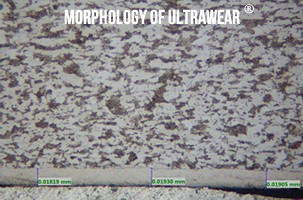

The process is called ‘ferritic nitrocarburizing’ and it imparts nitrogen and carbon into the molecules of the machined casting. The nitrogen and carbon enrichment of the base material enhance fatigue characteristics while forming a ɛ ‘epsilon’ carbonitride layer, commonly referred to as compound or white layer. This white layer forms a corrosive barrier and is very hard, yet ductile which increases resistance to wear and rotor life.

Ultrawear ® is a thermal chemical diffusion process. It is important to note that it is not a coating.

Ultrawear ® is a nanotechnology and alters the base material’s structure at the molecular level.

- Ultrawear ® forms a hard outer layer with hardnesses capable of exceeding Rockwell C 70. Even though it is hard it is ductile.

- Depths can vary from as little as 1 micron to as much as 100 microns.

- Ultrawear ® also forms an enriched diffusion zone, typically 10 (ten) Rockwell points greater than the core hardness. Ultrawear ®

diffusion increases base material fatigue. - Ultrawear ® is a “green” technology.

Other Benefits Include

- Reduce Cross-Section

- Cost Effective vs other FNC Processes

- Increase Material Tensile (Up to 40% in Base Material Properties)